Flat Products

A Plate can be produced from a slab and shaped into a thick, flat-rolled construction element and is available as discrete or coiled pieces. They can be supplied standard as well as customized.

Plates are produced in various makes such as carbon, alloy and stainless steel. They are renowned for their acceptance level, corrosion resistance and long life. The average thickness ranges between 5 to 200mm and overlaps with hot-rolled coil at lower gauges. The cold rolling process enables the production of thinner plates.

Due to features such as high performance and low maintenance, it is favored in architectural / construction trade circles. To ensure corrosion resistance and abrasion abilities, plates are incorporated as per precise procedures to cater to diverse industry requirements.

FISTCO offers a range of standard Grades of the product and HRC like EN, DIN,BS,ASTM & ASME.

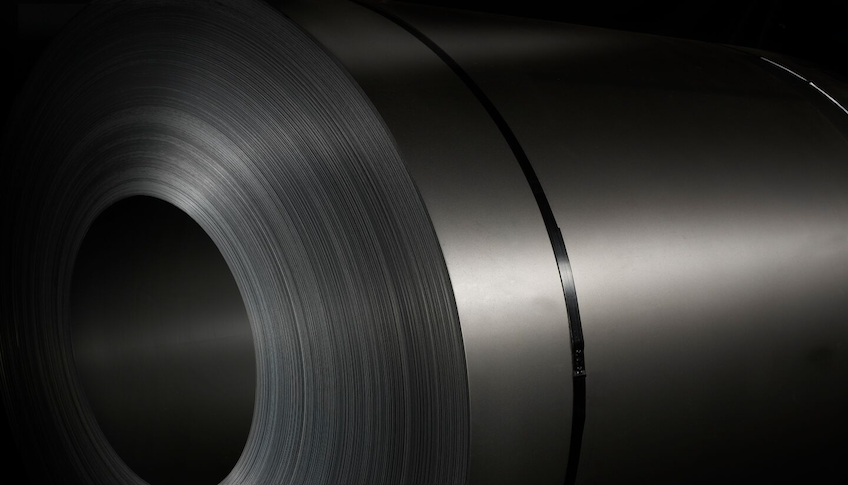

Hot-Rolled Coil

Hot-rolled coil (HRC) is the predominant finished steel

and the foundation for many steel-based industrial products.

Hot rolled steel is steel that has been roll-pressed at very

high temperatures—over 1,700˚F, which is above the re-crystallization

temperature for most steels. it becomes more malleable and can be

properly formed and shaped. These properties make hot-rolled

steel most suitable for structural components and other applications

Thickness: 0.2 – 20 mm

Width: 1000 – 2000 mm

Length: 4 meters – coil

Cold-Rolled Coil (CRC)

Compared to hot-rolled steel, cold-rolled steel has a nearly 20%

increase in strength through the use of strain hardening followed by

annealing and/or temper rolling. This process produce steel with

thinner gauges, closer dimensional tolerances and a wider range of

uncoated surface finishes. Cold-formed steel is the common term for

steel products shaped by cold-working processes carried out near room

temperature, such as rolling, pressing, stamping, bending, etc.

Cold rolled steel offer a variety of outstanding properties, including

easy formability and a smooth, clean surface, and are used in automobiles,

appliances, furniture, and many other everyday items.

Thickness: 0.2 – 3 mm

Width: 1000 – 5350 mm

Length: 4 – 27 meters

Galvanised Coil

It is the process of applying a protective zinc coating to steel.

The most common method is hot-dip galvanizing, in which parts are

submerged in a bath of molten zinc at temperatures of around 460 degrees

Celsius. The Zinc coating on the steel coil substrate acts as a barrier

between the atmosphere and the surface of the metal and prevent rusting.

Thickness: 1.6 – 12 mm

Width: 1000 – 2000 mm

Length: 4 meters – coil

PPGI

PPGI is pre-painted galvanized iron, also known as pre-coated steel,

coil coated steel, color coated steel etc., and typically with a hot dip

zinc coated steel substrate. Surface of galvanized steel evenly distributed

the layer of zinc materials, which plays the role of anodic protection for

base material, that means corrosion of zinc material give the protection of

the base material , and only when all the zinc coating is corroded ,can harm

done to the base metal inside. The properties of pre-painted hot dip galvanized

steel are tough coating, completed protection, low maintenance and long life.

Thickness: 0.3 – 3 mm

Width: 1000 – 5350 mm

Length: 4 – 27 meters

Plates

Our Cut-to-Length can process any coil to plates with following dimentions

Thickness: 0.3 – 16 mm

Width: 1000 – 5350 mm

Length: 4 – 27 meters

Chequred Plate

Steel chequered plates are extensively used as floor coverings in marine, stairways,

transportation equipment and for general structural purposes.

Thickness: 0.3 – 3 mm

Width: 1000 – 5350 mm

Length: 4 – 27 meters